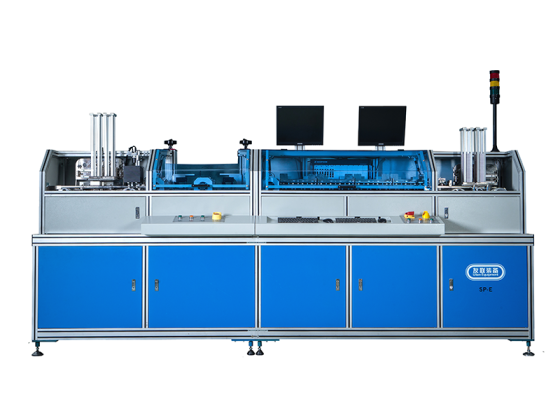

Module Testing & Encoding Machine

· Supports contact module, contactless module, dual interface module testing and data download

· The device can support up to 180 contact or 60 contactless readers

· Online rewriting.

- Information

Product Introduction

Introduction of Module Testing & Encoding Machine:

MET-E is mainly used for preparation before writing personalized data to IC chips, aiming to improve production capacity by shortening the data writing time. It first performs electrical performance testing, COS and initialization data writing of the chip to provide a basis for the subsequent personalized data writing process.

The device supports contact, contactless and dual-interface chip module strips to meet the needs of different types of chips. Customers can choose the appropriate module configuration according to actual production needs to improve flexibility and adaptability.

In addition, MET-E also provides an optional gun-breaking module, and the number of mold gun heads can be customized according to customer needs to further optimize production processes and efficiency.

Main Functions of Module Testing & Encoding Machine

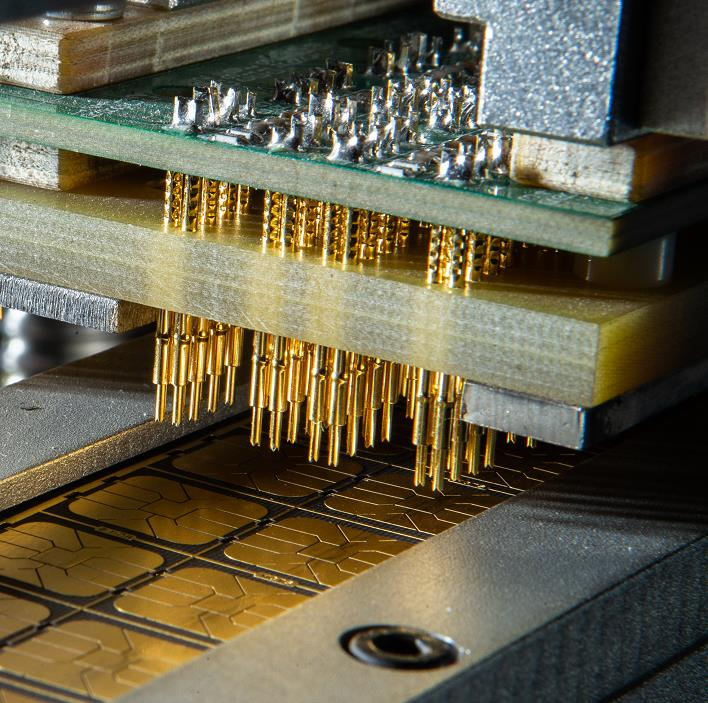

Main writing mechanism

Configured with 120 programming stations (readers and writers) or 180 programming stations, data can be written to 120 8-pin module chips or 180 6-pin module chips at the same time.

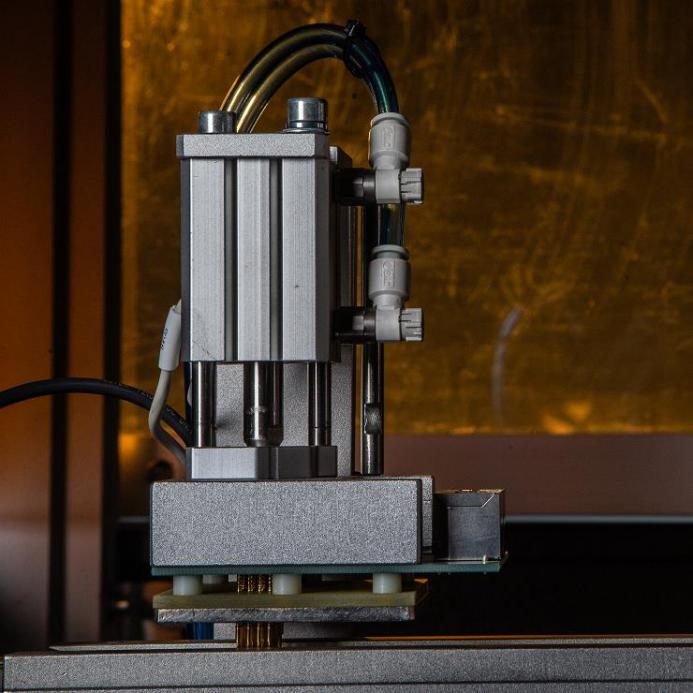

Rewrite mechanism

After the main write mechanism completes writing to the chip, the chip that failed to be written is rewritten at the rewrite mechanism.

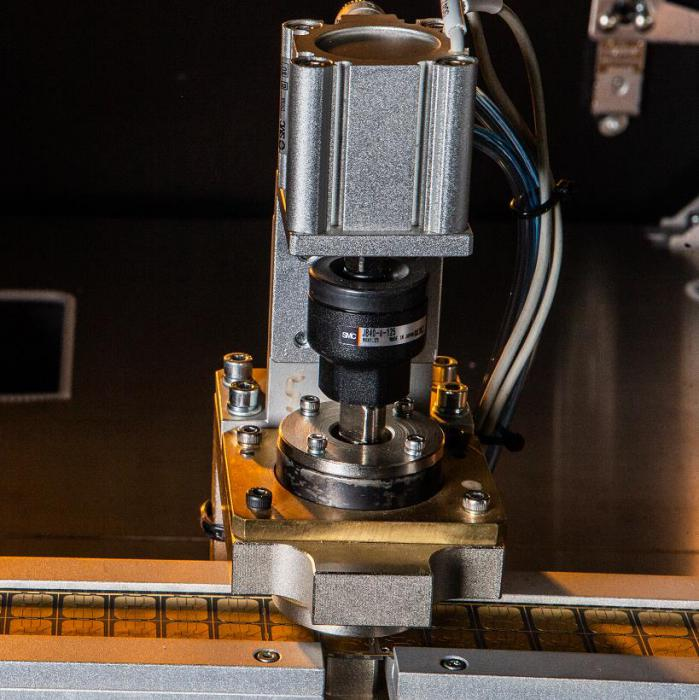

Punching mechanism

The chips that failed to be rewritten in the module strip are punched and marked at the punching mechanism.

Capacity Table

| Personalized time (S) | 5 | 10 | 15 | 20 | 25 | 30 | 35 | 40 | 45 | |

| Production capacity (UPH) | 8PIN 120 heads | 49000 | 31000 | 23000 | 18000 | 15000 | 12800 | 11000 | 9800 | 8900 |

| 6PIN 180 heads | 62000 | 42000 | 32000 | 25000 | 21000 | 18000 | 16000 | 14000 | 13000 | |

| Connectless 60 heads | 47100 | 27000 | 119300 | 14900 | 12000 | 10200 | 8700 | 7800 | 6900 | |

Parameter Table

| Equipment size and specifications | |

| Size | 4000×800×1500mm (L×W×H) |

| Weight | About 350kg |

| Power supply |

|

| Gas source |

|

| Tray Specifications | Material tray thickness 40~65mm |

| Strip size specifications |

|

| Probe life | 300,000 times |